As a crucial component of renewable energy strategies, understanding the financial anatomy of these projects is vital. Offshore wind energy represents a cost-effective and sustainable solution.

The main advantage is that you can choose a region that is more suitable for building such a project. Comparing different locations is essential, and the key part of that is the total price. We will analyze more on this topic in the following article.

Installation and Equipment Costs

The physical installation of offshore wind turbines is a colossal undertaking, demanding specialized vessels and extensive man-hours. An average installation cost of $1,000/kW masks the range of expenses, which can vary from $800 to $2,500/kW depending on project parameters.

Additionally, turbine costs, typically around $1,500/kW, add to the financial load. Each turbine installation, requiring about 100 vessel days, underscores the extensive logistical and financial planning needed.

Scale and Location as Important Factors

Economies of scale play a pivotal role in the offshore wind sector. Larger turbines in bigger projects can offer cost efficiencies, but this advantage is often offset by the challenges of remote locations and deeper waters.

As projects move further offshore, costs rise due to increased transportation distances and the complexity of installation in deeper waters. This balance between scale and location is crucial in determining the overall feasibility and cost-effectiveness of offshore wind projects.

The Advantage of Working with Established Companies

When selecting a company for an offshore wind project, comparing different firms is a critical step. Factors like experience, technological expertise, and financial stability play crucial roles in ensuring project success. Working with a well-known and reputable company can bring numerous benefits, particularly in a complex and costly field like offshore wind energy. One of the best examples in this industry is https://iqip.com/

Experience and Track Record

Established companies often have a proven track record in completing large-scale projects. Their experience in navigating the complexities of offshore wind installations, from permitting and environmental compliance to logistics and construction, is invaluable. A company with a history of successful projects is more likely to predict and manage the challenges that inevitably arise.

Technological Expertise

Leading companies in the offshore wind sector invest in research and development, ensuring they are at the forefront of technology. This expertise can lead to more efficient project execution and potentially lower costs in the long run. Advanced technology in turbine design, installation techniques, and maintenance can significantly impact the project’s overall efficiency and lifespan.

Financial Stability

Offshore wind projects require substantial capital investment. Working with financially stable companies ensures continuity and reduces the risk of delays due to financial constraints. Stable financing also implies the ability to invest in quality materials and skilled personnel, which are crucial for project success.

Supply Chain and Logistics Management

Established firms often have robust supply chain networks and logistics management capabilities. This is crucial in a sector where delays in the supply of materials or equipment can lead to significant cost overruns and project delays.

Risk Management and Safety Standards

Reputable companies tend to have stringent safety standards and effective risk management strategies. Given the high-risk environment of offshore construction, adherence to safety protocols is critical to protect workers and the environment.

Post-Installation Services

The relationship with the company doesn’t end with installation. Ongoing maintenance and support are crucial for the long-term success of the project. Established firms usually offer comprehensive post-installation services, ensuring the wind farm operates efficiently throughout its lifespan.

Operational and Maintenance Costs

The operational and maintenance (O&M) costs of offshore wind projects, often overlooked in the initial planning stages, form a significant portion of the overall lifecycle costs. These expenses, covering everything from routine upkeep to major repairs and upgrades, can dramatically affect the long-term economic viability of a wind farm.

Routine Maintenance

Regular maintenance is crucial to ensure the smooth functioning of offshore turbines. This includes periodic inspections, cleaning, lubrication, and minor repairs. The harsh marine environment, characterized by saltwater corrosion, strong winds, and wave action, necessitates more frequent and rigorous maintenance compared to onshore turbines.

Additionally, the remote location of these turbines adds to the logistical challenges and costs, as accessing them requires specialized vessels and trained personnel.

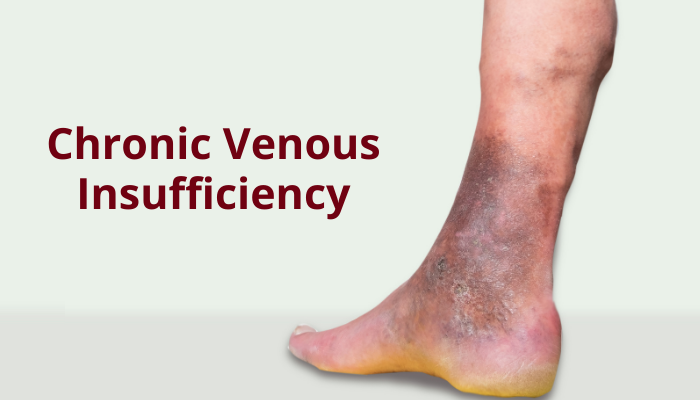

As we delve into the complexities of occupational hazards and the associated risks, it’s essential to acknowledge the perilous nature of certain professions, shedding light on occupations with the highest risk, a topic further explored in a separate piece focusing on safety concerns in diverse fields.

Major Repairs and Overhauls

Offshore wind turbines are subject to significant wear and tear, leading to the need for major repairs or component replacements over their operational life. Key components such as blades, gearboxes, and generators may require replacement or major refurbishment. These activities not only incur high costs for parts and labor but also result in downtime, during which the turbine is not generating revenue.

Technological Upgrades

The fast-paced advancement in wind turbine technology means that older turbines may become less efficient or compatible with new systems. Upgrading turbines with the latest technology can improve their efficiency and extend their operational life. However, these upgrades are costly and require careful financial planning.

Access and Logistics

The cost of accessing offshore turbines for maintenance and repairs is a significant factor. Specialized vessels, such as jack-up rigs or service operation vessels, are needed, and these come with high day-rate costs. Weather conditions also play a crucial role, as bad weather can delay maintenance activities, leading to increased costs and potential loss of revenue.

Staffing and Training

Skilled technicians are required for the maintenance and repair of offshore turbines. Given the specialized nature of the work, these personnel often command higher salaries. Moreover, ensuring their safety in the challenging offshore environment requires extensive training and adherence to strict safety protocols.

Insurance and Warranty Costs

Insurance costs for offshore wind farms are typically higher than for onshore farms due to the increased risks associated with the offshore environment. Warranty provisions also play a role in O&M costs. While manufacturers’ warranties cover certain repairs, the costs can escalate once these warranties expire.

Impact of Operational Efficiency

Efficient O&M strategies can significantly reduce these costs. Predictive maintenance, using data analytics to anticipate and address issues before they lead to failures, can help in optimizing repair schedules and reducing downtime. Similarly, innovations in turbine design that improve durability and ease of maintenance can lead to long-term cost savings.

FAQs

Do windmills pay for themselves?

Windmills, or wind turbines, can pay for themselves over time by generating electricity from the wind and selling it to the grid or using it to reduce energy bills. The payback time depends on the size, location, and cost of the wind turbine, as well as the price of electricity and the wind speed.

Why are wind turbines so expensive?

Wind turbines are expensive because they are large, complex, and durable machines that require high-quality materials, skilled labor, and specialized transportation and installation. Wind turbines also have to withstand harsh weather conditions, such as storms, lightning, and ice, and comply with safety and environmental regulations.

How big is a 5 MW wind turbine?

A 5 MW wind turbine is a large-scale wind turbine that can produce 5 megawatts of electricity at its maximum capacity. The size of a 5 MW wind turbine varies depending on the design and manufacturer, but typically it has a rotor diameter of about 400 feet and a tower height of about 300 feet.

How much does a 20kw wind turbine cost?

A 20kw wind turbine is a small-scale wind turbine that can produce 20 kilowatts of electricity at its maximum capacity. The cost of a 20kw wind turbine depends on the type, model, and supplier, but generally, it ranges from $50,000 to $100,000 before tax credits and incentives.

Last Words

Projects like these are not just financial investments; they are investments in our future. The costs involved reflect the value we place on sustainable, clean energy and the health of our planet.

As technology evolves and the industry adapts, offshore wind projects stand as beacons of progress in our collective journey toward a more sustainable and environmentally responsible world.